Nexcom released new EtherCAT controllers NET series which support C/C++ and IEC-61131-3 languages to simplify the development of advanced motion control applications.

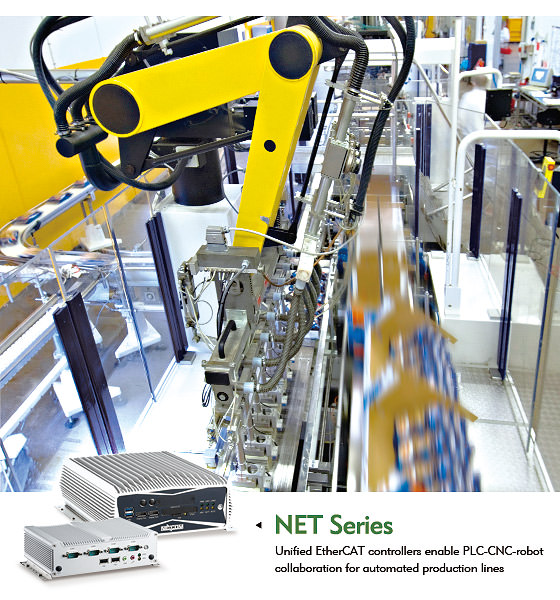

Featuring programming flexibility, the NET series enables machine builders and automation control engineers to fully leverage its powerful PC architecture and function libraries by using a programming language that best serves the control purpose. Aimed to modernize production lines, NEXCOM EtherCAT controllers allow for close collaboration of PLC systems, industrial machines, and robots, taking factories one step closer to Industry 4.0.

To modernize production lines, the NET EtherCAT controllers offer design flexibility and integration with C/C++ and IEC 61131-3 support. The multi-language feature makes the NET series an apt platform for both motion control and robot applications and PLC automation use cases. With a unified controller like the NET series, engineers can build highly automated production lines where CNCs, high-speed pick-and-place robots, conveyor systems, and other industrial machines all work in concert.

For complex motion control and robot applications, the NET 3600E-ECM bundle makes an ideal choice. The bundle includes a powerful EtherCAT Master controller and the programming software NexECM. Supporting C/C++, NexECM features high level functionality, EtherCAT Master library, and CiA 402 motion control library. The software can automatically detect EtherCAT slaves, such as EtherCAT servo drives and EtherCAT I/O modules, connected to theEtherCAT Master controller. More importantly it simplifies the buildup of advanced kinetic control and enables smooth movement of coordinated axes required of individual CNCs and robots.

As for PLC control systems, the NET 104-CDS bundle integrates an EtherCAT Master controller pre-installed with CODESYS SoftMotion. The bundle provides SoftPLC functions with support for IEC-61131-3 standard programming languages including Ladder Diagram (LD), Instruction List (IL), Function Block Diagram (FBD), among others. Engineers can easily devise and maintain motion sequence for sophisticated coordination of axes used in sorting, packing, material handling, and other sequential operations.

NEXCOM EtherCAT Master controller has been applied to factory and machine automation applications. In a wet wipe factory, NEXCOM EtherCAT Master controller is used in an automated pasting system to coordinate delta robots, conveyers, sensors, and gluing and labeling equipment to paste covers on wet pipe packs.

Main Features

- EtherCAT technology with NexECM/EtherCAT Master, and RTX 2012

- Built-in EtherCAT configuration tool for fast implementation

- Seamless integration with CoE protocol and advanced API for CiA® 402 profile

- EtherCAT communication cycle up to 250 µs

- Support distributed clocks technology

Certified Device List:

| EtherCAT Servo Drive | EtherCAT I/O Module |

| Yaskawa Sigma-5/Sigma- | NEXCOM AXE-9200 |

| Hiwin D2, D1 | NEXCOM NEIO Series |

| Omron R88D | VIPA SLIO Series |

| Delta A2E | Prima C1, E1, E2 Series |

| Servotronix CDHD | Beckhoff EL1, EL2, EL4, EL30 |

| Sanyo PB4D | SYN-TEK ESC5500, ESC6022 |

| Panasonic MINAS A5B | |

| Mitsubishi MR J3-T04 |

CPU and Models:

| Model: | CPU: |

| NET104-CDS | Intel® Atom™ processor E3826, 1.46 GHz |

| NET104-ECM | Intel® Atom™ processor D2550, 1.86GHz, 1x mini-PCIe with two antenna holes |

| NET3140P2E-ECM | Intel® Core™ 2 Duo processor P8400, 2.26 GHz, PCI and PCIe expansion slots |

| NET3500-ECM | Intel® Core™ i5-520M processor, 2.4GHz, one PCI expansion slot |

| NET3600E-ECM | Intel® Core™ i5-3610ME processor, 2.7 GHz |