Industrial Robotic Automation – Not Only For The Big Players:

Robots today, in many ways, exercising the science fiction books and movies, and its technology rapidly moving forward every day.

The robots do not need air to breathe, they’re resistant to harsh environmental conditions. That is practicly what make robots the perfect workers for difficult and routine roles

The industrial robots allow accuracy and efficiently even in working continuously for hours. Robots today are common especially in the production line of large companies, but also gradually penetrate to production lines of smaller factories due to their economic efficiency.

And why ?

Today most manfucaturing applications can be implement by standard robot as shelf product, due to better control systems. Unlike in the past, where any application required custom application-specific robot.

What is control system?

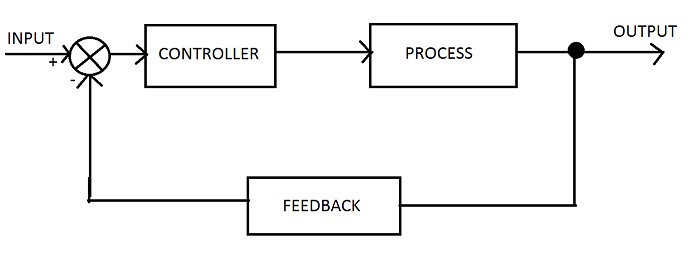

Control system can be defined as mechanism that manage and direct process, equipment or machine.There are two common classes of control systems:

- Open Loop – These systems describes uncontrolled systems, the output is generated based on inputs. For example: Moving element from place to place in a predetermined distance. In an ideal world a system like that, which required starting point, ending point and distance, should not be a big challenge to operate…. but what if we will have to consider environment, changing weight of the crate and the need for maximum accuracy the start and end points.

- Closed Loop – These systems contain correction unit which operate based on feedback. The system response takes into account the process feedback. The feedback information is picked from sensor (Camera, Pressure gauge, Altimeter, etc.)

One of the most common sensors in industry is camera. The camera is actually an optical sensor that allows us to get a visual indication from environment.

Cameras in Industrial feedback systems:

The image processing capabilities allow us to use the camera as Rangefinder, Thermometer, motion detection, etc….

In general, all the optical sensors designed as matrix of sensitive material to photons (light energy) and divided into two families:

- CCD – Charge Coupled Device – A veteran technology considered as better quality, mainly because the CCD sensor is physically big, therefore allows more light to be absorbed. This technology has high immunity to noise. On the other hand CCD sensor support low reading speed and it is expensive sensor compered to CMOS.

- CMOS – Complementary Metal Oxide Semiconductor – CMOS sensor is cheaper compared to CCD, it is also smaller, therefore it is convenient to combine CMOS sensors inside mobile products such as smart phones, tablets, laptops etc..The downside is the noise sensitivity.

CMOS based detectors usually contain noise filter and signal amplifier inside the sensor.

Cameras manufactures build a camera around the sensors, which function as sensor sampler which produce a visual indication based on the data arriving from the sensor.

- Security Cameras (IP) – contain internal encoding mechanism so the camera output information will be partial (which is good enough for security systems).

- Machine Vision Cameras – contain more sensitive mechanism in order to support raw data, that will enable an accurate processing.

Information absorption process from the sensor generates deviations and distortions, cameras normally contain error correction techniques, for example global shutter technique, which allows capturing high quality image even if the object or camera is in fast motion.

the detector to gather information bow image quality even when the object or camera in Swift movement.

Contact us for additional information